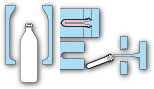

The One-Step method -- from PET granule to finished bottle -- all processes are completed on one integrated machine. This means the injection-molded preform is withdrawn from the injection cavity while still hot enough to be stretch blown to form the bottle. No extra heating is required, and since preforms are not stockpiled to be blown at a later date, but are freshly molded every time, there is no risk of surface damage from preforms knocking together during storage or transportation. One-Step method is highly suited to small and medium scale production lines.

PET absorbs moisture from the atmosphere. This must be removed by a dehumidifying drying before processing.

Dried PET pellets are compressed and melted by a rotating screw.

Molten PET is injected into the injection cavity and cooled rapidly to form a a€?preform? (The test-tube-like form from which bottles are blown is known as a preform).

The temperature of the preform is adjusted to the correct profile for blowing.

The hot preform is simultaneously stretched and blown (thereby orienting the crystals of and strengthening the PET*) into a shaped blow mold to form a tough, lightweight container. PET that is heated to a temperature where its chain-like molecules are sufficiently mobile to uncoil instead of breaking when extended, can be oriented by stretching. Stretching applied from two directions at right angles, as in stretch blow molding, gives biaxial orientation. Oriented PET contains closely packed chains aligned in the directions of stretch. The material is stronger because the molecules act together instead of individually. The tensile strength of oriented PET is several times that of the unstretched material and the impact strength, barrier and chemical resistance are also significantly improved, so bottles can be lighter without sacrificing performance.

The finished container is ejected.

How Acetaldehyde affects the product? With the growing popularity of PET containers, water companies are becoming more aware of AA and how it can affect product taste. In most cases, the flavour of AA is barely detectable during beverage consumption. Carbonated soft drinks, for example, have very sweet or tangy flavours that mask the slight taste of the plastic. But the very delicate, or even imperceptible, taste of pure water is not strong enough to mask acetaldehyde, and so it is easier for the consumer to notice the presence of AA. Consumers rank taste as the number one criterion when selecting a water brand. They look for purity that cannot be found in tap water. Water companies retain customer loyalty by delivering consistent, high quality products that fulfil the brand promise. Even minor differences in taste will compromise brand integrity and affect sales.

How is AA generated in PET bottles? During bottle manufacture the resin pellets are dried and melt-processed at high temperatures (higher than 2600C) and are injection moulded into preforms. The preforms are then reheated and stretch-blow moulded to form a container. It is during the melt-processing stage that AA is generated.

Optimization of the molding conditions by way of minimizing melt temperature and residence time can aid in minimizing AA generation. However it cannot be entirely eliminated. AA produced during processing is retained or trapped in the polymer matrix of the bottle or container. Since AA boils at below room temperature, it eventually migrates out of the PET into the atmosphere or into the packaged contents, affecting taste. The amount of AA that migrates is directly related to storage time and temperature. There are a number of ways that AA levels can be significantly reduced so that taste is not affected. The first step is choosing the right PET resin. Resins are available with properties that are specifically tailored to the needs of water containers. For example, Voridian Aqua PET resins 18696 and 20837 are considered leaders in low AA levels. Each has a low intrinsic viscosity (IV) of 0.72 and 0.76 respectively. The low IV minimizes AA generation during melt-processing.

Because bottle performance is important, these resins are designed so that the low molecular weight does not compromise mechanical properties of the finished bottle.

Certain water markets seek AA levels that are lower than even the most progressive polymers will allow. In these cases, the low AA resins are combined with an AA a€?scavenger? AA scavengers are blended with the PET as it is melted in the injection-moulding phase. The scavenger reacts or combines with AA to a€?lock?it into the polymer matrix so that it cannot migrate into the product. Scavengers can further reduce AA levels in preforms up to 70-80%.It is important to choose a PET solution with the proper balance between low AA levels and high performance. This can yield a bottle with excellent mouldability and optical qualities. A low-AA resin should blend well with colors and tinters to produce a package with the look and feel that supports the brand.

|

PET is fully recyclable where facilities exist. It is given the recycling code 1. Post-consumer recycled PET (PCR PET) can be used for clothing and carpet fiber, and fiberfill for stuffing articles such as pillows. Recycled PET can be used to makenew bottles for non-food products such as cleaning products. To make food and beverage containers out of PCR |

A simple recycle method popular is to only crush mold PET products, then mix crushed PET granules into virgin PET resins, but the percentage should be no more than 20%. High regrind proportion will cause variance on melt's viscosity, color and odor. Hopper magnet is suggested in injection machine when using recycled material.